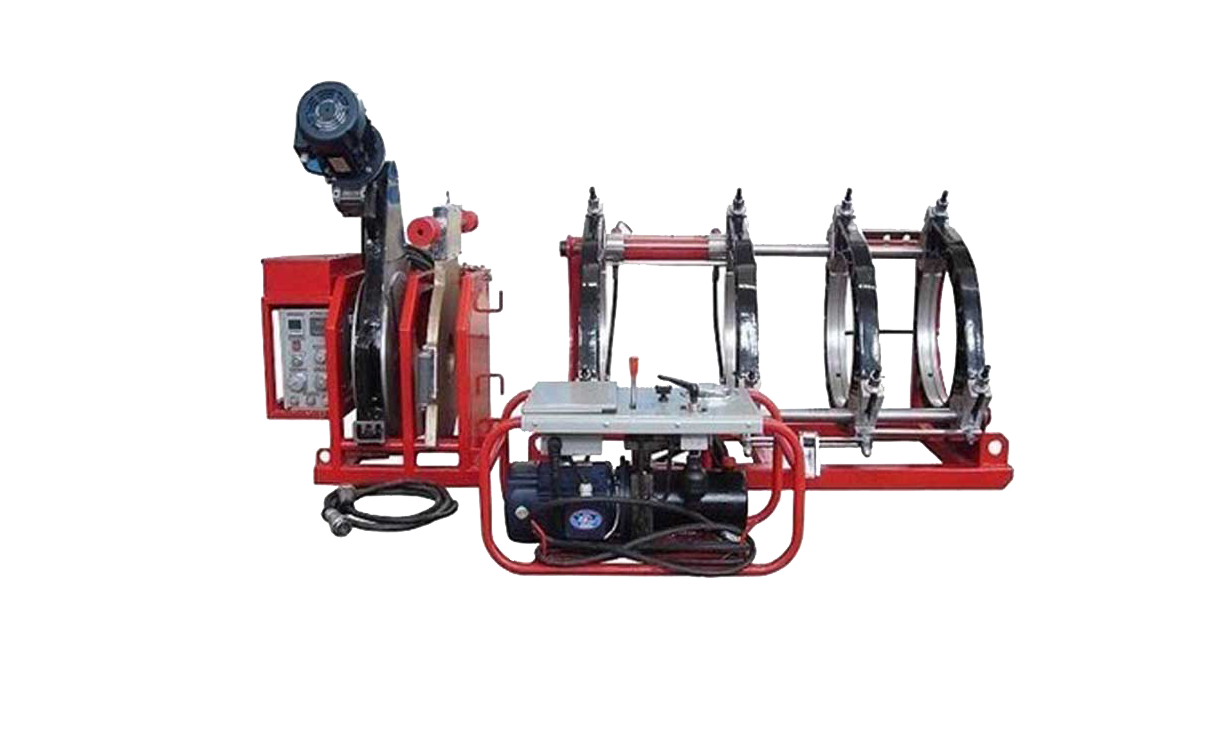

Butt Fusion Jointing Machines

PLAST1 sells HDPE Butt Welding Equipment.

In the poly welding process known as butt fusion welding, butt welders are used to scrape, heat and weld HDPE pipe together.

Butt welders can come with manual hydraulics or electric hydraulics. All butt welders (except for self-contained welders) need a power supply for the heater plate and milling cutter/scraper. Electric hydraulic butt welders also use the electricity supply for the hydraulic system, used to hold the pipe while it is being scraped, heated and during cooling.

Will you be poly welding on site without a reliable power supply? PLAST1 also lends portable generators, designed to be used with poly welding equipment.

Below is the list of Butt Welders that PLAST1 Piping Systems can supply:

160 mm Butt Welding – Butt Fusion Machine (Electric Hydraulic)

Buy this 160 mm butt fusion welder for welding HDPE pipe between 63 mm and 160 mm diameter in electric hydraulic mode. For use in the field, you may need a 5.9 kVA portable generator.

The 160 mm butt welder comes complete with an extractable heating plate, extractable milling cutter, electro-hydraulic gear case, heating plate and milling cutter support, tool kit, and stub end device (spider).

** set of inserts OD 63, 75, 90, 110, 125, 140 mm, main clamp OD 160 mm.

Power requirements: 2.45 kW – Minimum required of a 3.5 kVA generator 240 V, single phase.

250 mm Butt Fusion Machine (Electric Hydraulic)

Buy this 250 mm butt fusion machine for welding HDPE pipes between 90 mm and 250 mm diameter in electric hydraulic mode. You may need a 5.9 kVA portable generator to power your poly welding equipment on site.

250 mm fusion welding machine hire comes complete with an extractable heating plate, extractable milling cutter, electro-hydraulic gear case, heating plate and cutter support, tool kit, and stub end device (spider).

** set of inserts OD 90, 110, 125, 140, 160, 180, 200, 225 mm, main clamp OD 250 mm.

Power requirements: 3.85 kW – Minimum required of a 5.9 kVA generator 240 V, single phase.

355 mm Butt Fusion Machine (Electric Hydraulic)

Purchase this 355 mm butt welder for HDPE welding of PE pipe between 90 mm and 355 mm diameter in electric hydraulic mode. Buy this fusion welder along with the 6.8 kVA portable generator – perfect for poly welding equipment being used on site.

The butt welder comes complete with an extractable heating plate, extractable milling cutter, electro-hydraulic gear case, heating plate and milling cutter support, tool kit, and stub end device (spider).

** set of inserts OD 90, 110, 125, 140, 160, 180, 200, 225, 250, 280, 315 mm, main clamp OD 355 mm.

Power requirements: 4.85 kW – Minimum required of a 6.5 kVA generator 240 V, single phase.

450 mm Butt Fusion Machine (Electric Hydraulic)

Buy the 450 butt fusion welding machine for butt-welding polyethylene pipes with an outside diameter between 200 mm and 450 mm diameter in electric hydraulic mode. Contact our team to hire a suitable generator, for butt welding in the field. The butt-welding machine includes a jib crane to assist with the milling cutter and heater plate, which are quite heavy due to the large capacity of the butt welder.

This but welder comes complete with an extractable heating plate, extractable milling cutter, electro-hydraulic gear case, heating plate and milling cutter support, tool kit, and stub end device (spider).

** set of inserts OD 200, 225, 250, 280, 315, 355, 400 mm, main clamp OD 450 mm

Power requirements: 8.38 kW – Recommended generator for field operation – 11 kVA 415 v, three phase.

630 mm Butt Fusion Machine (Electric Hydraulic)

The 630 butt welder machine is perfect for butt-welding HDPE pipes with an outside diameter between 315 mm and 630 mm diameter in electric hydraulic mode. Contact our team to hire or buy a suitable generator, for on-site butt welding.

The butt welding machine includes a jib crane to assist with the milling cutter and heater plate, which are quite heavy due to the large capacity of the butt welder.

When you buy this poly welding equipment, it includes an extractable heating plate, extractable milling cutter, electro-hydraulic gear case, heating plate and milling cutter support, tool kit, and stub end device (spider).

** set of inserts OD 315, 355, 400, 450, 500, 560 mm, main clamp OD 630 mm

Power requirements: 12.35 kW – Recommended generator for field operation – 16 kVA 415 V, three phase.